Stone crushers commonly classified by the degree to which they fragment the starting material, with primary and secondary crushers handling coarse materials, and tertiary and quaternary crushers reducing ore particles to finer gradations. Each crusher is designed to work with a certain maximum size of raw material, and often delivers its output to a screening machine which sorts and directs the product for further processing.Typically, crushing stages are followed by milling stages if the materials need to be further.

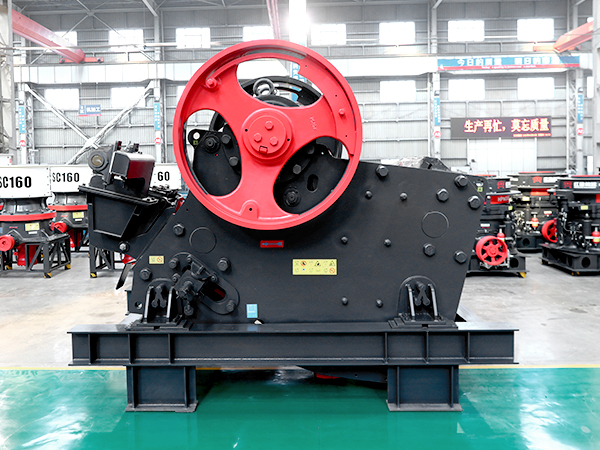

Stone Crusher

Feed Size ≤25mm

Capacity 5-600/h

Exported Countries Germany, France, Sierra Leone, Russia, Netherlands, United States, Canada, Chile, United Arab Emirates, Saudi Arabia, Iraq, Kyrgyzstan, Tajikistan, Kazakhstan, Uzbekistan, Tanzania, Nigeria, Rwanda, Liberia, Singapore, Thailand, Cambodia, Indonesia , South Korea, Philippines, etc.

Applied Materials Cement, limestone, rock, granite, aggregate, metallurgy, pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, rocks, ore, glass, cement clinker, etc.